July 1927

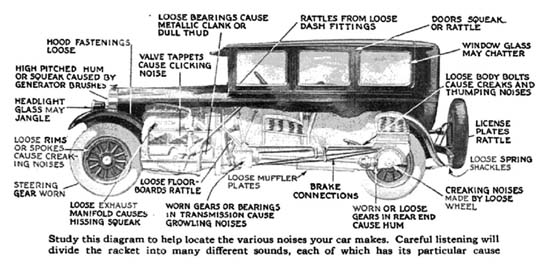

STOP THE NOISES IN YOUR CAR

by Martin Bunn

"Hey, Joe!" Gus Wilson shouted to his partner, "see if you can't stop that infernal racket outside. I can't even hear this motor run, much less tell if there are any noises in it!"

Joe Clark swung open the door of the Model Garage and stepped outside. A second later the roaring and clattering subsided into a dismal clanking and then ceased altogether.

Gus, with a grunt of satisfaction, picked up his stethoscope and soon was completely absorbed in testing the car he was working on. The motor was purring as quietly as a contented cat, but Gus listened carefully at every point where there was any possibility of noises that would reveal incorrect adjustments in the mechanism.

"What are you doing -- listening for the heartbeats?" asked a young fellow who had strolled up so silently that Gus hadn't heard him.

"I am," replied Gus, "if that's what you want to call 'em. Was that your car making all the racket outside?"

"Yes, but don't put that stethoscope of yours near my motor. It would bust your eardrums."

"So I heard," Gus growled. "When are you going to overhaul that junk pile anyway?"

"Junk pile! Where do you get that stuff?" snapped Will Otis, the owner of the noisy car.

"Maybe I'm anticipating a bit, Otis." said Gus with a grin. "If the car isn't junk by now, it will be very shortly if you leave it in that condition. Hang around a few minutes till I get this job out of the way and I'll have a look at it. You'll have to take me for a ride, though -- I want to find out what else I can hear besides motor noises."

When the two men were in the noisy car, Otis stepped on the self-starter and the motor started with a clattering roar. They drove about a mile, which included one rather steep hill. Gus made no remarks during the ride, but he was making mental notes of the various queer noises that were assailing his cars.

"I'm afraid it's going to be a long list," he said as they pulled up in front of the Model Garage. "Some of the troubles are your own fault and the rest of 'em are just natural wear or things that are loose.

"Better make a list so you won't forget any of 'em. First there's a dull thump that means a loose main bearing, I'll bet a hat. Then there's at least two connecting rods that need taking up. You can hear the metallic clank they make clear enough. Those clicking noises are loose valve tappets, and I wouldn't be surprised if the cam shaft is a trifle loose, too.

"That rumbling, grating noise that comes and goes with changing motor speeds probably is a loose timing chain that hits the side of the case now and then. And the rattle when you step on the throttle sounds to me like loose pistons. By the way, when did you put grease in the transmission last?"

"It must have been nearly a year ago," confessed Otis sheepishly. "I forgot about it, I guess."

"It costs money to forget things like that," said Gus. "It sounded dry as a bone. I hope the gears and bearings aren't worn too badly. The rear end has quite a hum. I suppose you haven't put anything in the differential case for a year, either."

"I guess that's right," admitted the other.

"You ought to have those things fixed," said Gus. "The question is, though, do you want me to fix everything or do you want to do some of the work yourself? All the things I mentioned are shop jobs, but there's plenty of noises about the car that you can fix yourself, if you want to save money."

"Sure, I want to save money," replied Otis. "If I don't, I won't have any to pay your bill for the rest of the work. What are the things I could fix?"

"Don't worry about them until I get rid of the motor, transmission and rear end noises," Gus advised. "It will be much easier to find the smaller noises after the big ones are cured."

"All, right," Otis agreed. "I'll leave the bus here and you can get busy on the work you've mentioned. When shall I come back?"

"In about a week," suggested Gus.

Otis showed up about a week later and Gus was ready for him.

"Take me for another ride," said Gus, "and see if you notice any difference."

Otis said nothing until they had driven several blocks.

"I can hardly believe it's the same car!" he burst out enthusiastically. "Now I can see why you didn't want to have me bother about the rest of the noises. They were drowned out by the ones you fixed.

The motor sounds fine now, and the hum in the rear end is gone, but there's a fine collection of rattles and squeaks I never noticed before. Where do they all come from?"

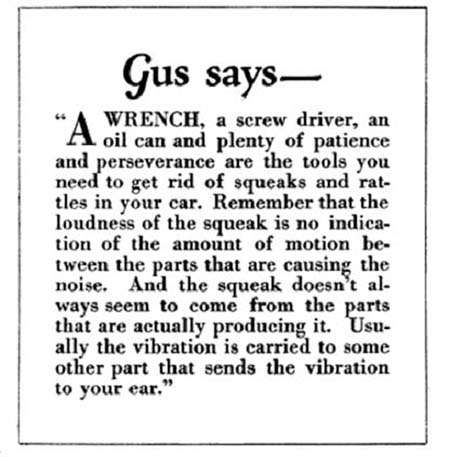

Gus smiled. "That's for you to find out, "he said. "Finding squeaks and rattles is just a matter of patience and keeping at it. Rattles are easier to find than squeaks because a rattle always means something is loose somewhere. Squeaks are hard to find because parts can be fastened together so tightly that you can't detect any looseness, and yet the jounces and jars will make them rub together enough to squeak like the dickens.

"The first thing to do is to get out your wrench and screw driver and go over every nut and screw you can find -- and from the way this car rattles, you'll find plenty of loose ones.

"It's surprising what a loud rattle can come from a small part that's just a trifle loose. At certain motor or car speeds, the loose parts get to vibrating. The smaller the part, the faster the rattle. Keep that in mind if you hear a real fast rattle, you know it must the some small part like the license plate or a section of the piping or perhaps one of the small rods that work the spark and throttle.

"Those clattering noises you hear only when you strike a bump in the road are usually made by some large part that's worked loose. Worn brake rod clevis and spring bushings make these parts clatter like sixty when you go over bumps. Of course there isn't any way to tighten up on spring bushings or brake rod clevis bearings -- you've got to replace them. Sometimes, though, most of the wear is on the clevis pin or the bolt that goes through the bushing in the end of the spring. In that case you can get rid of a lot of the looseness by using new pins and bolts."

"Why can't I just tighten the nuts on the end of the spring bolts until they bind a little bit?" asked Otis.

"Don't try any bum mechanic's job like that!" Gus growled. "In the first place, it won't work because spring bolts are built with a shoulder that keeps the nut from doing anything except stopping it from turning. In the second place, the bolt wouldn't stay tight for any length of time even if you screwed the nut on hard enough to cramp the spring clip against the end of the spring.

"That's nearly as bad as the job I saw a fellow who called himself a mechanic do on a brake rod clevis. He put it on the anvil and pounded it with a hammer until he had the holes oval in shape. They stayed tight for almost two weeks," Gus concluded.

"Oh, I wouldn't do anything like that," Gus grinned. It had been on the tip of his tongue to suggest that particular idea.

"Now, about those squeaks, "Gus continued as they stopped in front of the Model Garage, "don't be discouraged if you can't seem to find them at first. Remember that a cricket can make a whale of a noise just by rubbing some of its parts together. Wherever there's any chance for two surfaces to rub together, no matter how slight the motion is, there's a chance for a squeak.

"Squeaks are the result of vibration, and vibration is set up between two surfaces that are rubbing together only when there is the kind of friction you get when the surfaces are dry. Dry wood rubbing against dry wood or against metal will start vibrations that travel through the whole mass of wood or metal. Then the air carries these vibrations to your ear and you hear squeaks.

"That's why a car doesn't squeak so much when you are out in the rain. The water gets between the rubbing surfaces and lubricates them just enough to stop vibrations. Also, the water swells the wood and makes the joint much tighter, thereby eliminating friction.

"Wood wheels that squeak after a spell of dry weather can be cured by throwing a pail of water over them. Rattling floor boards sometimes can be quieted in the same way.

"Of course, oil stops squeaks much better than water because it doesn't dry out in a few days. But you wouldn't want to squirt oil all over your car on the chance that it might stop a couple of squeaks you can't locate.

"If you suspect that a squeak is coming from a particular spot -- say from the edge of one of the doors -- you can test it by putting a little oil on the surfaces that are worn bright by friction and see if the squeak stops. If it does, you can tighten up the fastenings of the door so there won't be any chance for motion.

"And don't jump at conclusions in deciding where the noise is coming from," Gus continued. "Sometimes one loose part will make a noise that is a good imitation of the noise you are likely to hear from some other part. A fellow came in here the other day to have the main bearings of his motor tightened up. He had heard a dull thump whenever the motor was pulling hard on a hill. I found the trouble, but it had nothing to do with the bearings of the motor. One of the bolts that held the motor in the frame was loose, and every time he opened the throttle and the motor began to labor, it just naturally bounced up and down with a thump that certainly sounded like main bearings.

"Then there was another chap who came in to have the commutator on the generator touched up because he said it was squealing like blazes. Come to find out, it was the stuffing box bearing on the water pump. He had forgotten to lubricate it, and the dry packing was setting up enough friction to produce a nice, loud squeal.

"One queer noise that bothered me for a while in a car I was working on turned out to be loose plates in the muffler. At certain speeds downhill, the loose plates would slide forward, closing up the passages. Then the gas pressure would slap them back again with a sound that was a cross between a clank and a thud."

"There's a bit of a commutator squeal from the generator of this car," Otis interrupted. "What's the best way to get rid of it?"

"Don't do anything," Gus replied. "I looked at the commutator and it seems to be in good condition. Often a commutator will develop a squeak that will go away by itself if you let it alone. Of course, if the commutator is worn or the brushes get so loose in the holders that they start chattering at certain speeds, you ought to have the commutator trued up and fit new brushes. Sometimes the commutator will take on a kind of dirty glaze that makes it squeak. Wiping it off with a rag and a little gasoline will usually fix that particular trouble. It isn't a bad idea to clean the commutator that way once in a while, anyway, and while you are about it, scrape the accumulated carbon dust that is ground off the brushes out of the slots between the copper bars."

"Gee!" exclaimed Otis, "I can see I have a lot of heavy detective work ahead of me to smoke out all the squeaks on this car."

"That's the penalty for having a quiet motor," said Gus. "Keep at it, though and eventually you'll at least get rid of the worst noises."

END

L. Osbone 2019