March 1929

HOW THE IGNITION SYSTEM WORKS

by Martin Bunn

Harnett was bubbling with indignation. His trim, white mustache twitched like an angry rabbit's.

"You fellows think you're slick, don't you?" he rasped. "Try to trim me, will you? That new garage down the street'll do the job for half your price, and I'm heading for there right now, by Henry!"

"Sorry you feel that way about it, Mr. Harnett," said Gus Wilson mildly. "We quoted you a fair price for overhauling the ignition system on a car like this. It was as low as we could make it for a good job, and that's the only kind we do here at the Model Garage."

"Save the bunk for someone else!" the angry man growled as he slammed the door of his car. "It'll be a long cold day before you see me around here again!"

"Another good customer gone," groaned Joe Clark, partner of Gus in the Model Garage, as the car rolled away.

"That new garage will take all our business away if we don't watch out."

"I'm not worrying so long as we turn out good work at fair prices," Gus smiled. "After that robber's roost down there stings him good and proper he'll be glad to come back to us!"

A few weeks later, Joe popped out of the tiny office with a broad grin on his face.

"You win, Gus," he said. "Harnett's on the wire. Says he's stuck about five miles down the road and will you please come and get him."

Harnett was sitting behind the wheel with a glum expression on his face as Gus drove up with the service car.

"I'll apologize for what I said the last time I saw you," he smiled sheepishly.

"I didn't know good work when I was getting it until those high-binders played me for a soft snap. They didn't charge much, but they didn't do anything. This makes the third time the ignition has given out. They said it was all right just before I drove out here."

Gus raised the hood and removed the distributor head. Then he examined the contact points. He got out a tiny wrench, made a slight adjustment, and replaced the distributor head. "Now try it," he ordered.

Harnett stepped on the starter and to his amazement the motor started at once.

"As easy as that!" he marveled. "Say Gus, stick an extra five spot on the bill and see if you can't get it into my thick head just how an ignition system works. I'm tired of getting stuck on the road with little troubles just because I don't know the first thing about it."

"Glad to," agreed Gus. "Follow me back to the garage where we can be comfortable.

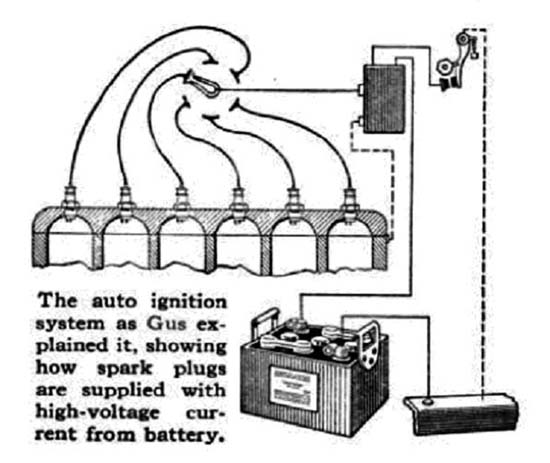

"Now," he continued, when they were seated in his office, "this ignition business turns out to be simple when you get right down to its workings." He drew paper and pencil from one of his pockets. "First we'll draw a storage battery, because that's where the juice comes from. Storage battery juice hasn't much kick behind it, only six volts.

That's not much pressure, but there's plenty of current. Sort of like a big pipe with a lot of water flowing through it at low pressure. If you slapped a nozzle on the end of such a pipe it wouldn't squirt out like a fire hose. It'd just ooze out.

"If you put a current of electricity with no more push behind it than that up against the job of jumping the gap in a spark plug, it couldn't come near making the grade. So what has to be done is to take that low pressure current and use it to produce a current with a whole lot of pep. Sounds like trying to pull yourself up by your boot straps, but it really isn't because we don't need much current at the peppy high voltage. We can sacrifice most of the volume to gain pressure."

"Then," interrupted Harnett, "if you get electricity at high enough pressure it will squirt off the end of a wire like water out of a fire hose?"

"In a way," Gus explained, "only the water will squirt in any old direction, while the high-voltage electric current will only jump across a gap in the circuit. Electricity always flows in a circle back to where it started from.

"But let's just forget about ignition switches and other fancy business and see what we actually do with the six-volt battery current. This little square thing I'm drawing now is supposed to be the spark coil, and this funny gadget right next to it is the contact breaker or timer. One terminal of the battery is wired to the frame of the car and there's a wire from the other pole of the battery is wired to the frame of the car and there's a wire from the other pole of the battery to the spark coil. There’s a wire from the spark coil to the insulated, stationary contact point in the timer. We'll put in a dotted line to represent the path of the current from the moving contact of the timer back to the battery by way of the frame. That's all there is to the primary or battery circuit except the ignition switch that we don't bother about and a fixed condenser connected across the contact points of the timer."

"The timer is what you fixed on my car?" Harnett questioned.

"That's right," Gus answered. "There was nothing the matter with your timer except that the boob who adjusted it forgot to tighten the lock nut and the stationary contact backed away until the moving contact couldn't touch it at all."

"What does the battery juice do inside the end?" asked Harnett.

"I was coming to that," Gus explained. "All it does is to circulate around a coil of heavy wire.

Inside the coil is a core made up of a bundle of iron wires. When you treat iron that way it becomes a magnet, just as it does in a doorbell.

"All you do with the juice from the battery," Gus continued, "is to make the core of the coil magnetic. And after the current has magnetized the core you cut off the juice by opening the contacts in the timer.

"Now comes the part that seems mysterious but really isn't. Wound on top of the coil of heavy wire are thousands of turns of very fine wire. That's called the secondary. One end of the coil is grounded on the frame of the car. We'll show that by a dotted line. The other is connected to an insulated metal finger that turns around inside the distributor head, making and breaking a series of contacts.

Each one of the contacts in the distributor is connected to a different spark plug.

"What actually happens is that we make the core magnetic by using the juice from the battery, and then we use that magnetism to generate the high voltage current. Magnetic lines will create a current in a wire whenever you move the wire across the lines. In a regular dynamo, you move the wire. In a spark coil the wire stays still and the magnetic lines move like lightning when the primary current is cut off."

"Why do you need so many turns of fine wire? I should think the magnetic lines would have more effect on heavy wire," Harnett interrupted.

"What you want is plenty of high voltage, and the voltage generated depends on the number of turns, not on the size of the wire," said Gus.

"Seems simple enough," Harnett admitted, "Now, if it's not asking too much, I'd really like to know why your price for overhauling the ignition was so much higher than the other fellow's. I know you'd do good work, but what is there to do besides cleaning the spark plugs and filing and adjusting the contact points?"

"There's lots more," replied Gus. "First I'd want to test the little spring that holds the contact against the cam and put a new one in if it was getting weak. Then after I got the timer in bang-up good shape, I'd want to put in all new high-tension cable between the distributor head and the spark coils. Yours is old and cracked and leaks juice all over the place when it gets wet. If you don't believe it grab one of the wires on a rainy day while the motor is running.

"Then, of course, I'd want to test the distributor and make sure it wasn't leaking, and after that I'd go over the spark plugs, replace the bad ones, test the spark coil, and then inspect every single connection. When I got through, your ignition would be just as good as when the car left the factory -- and maybe a bit better!"

END

L. Osbone 2019